Plastic Extrusion Manufacturing in China

Discover the possibilities with our custom plastic extrusion services. We can manufacture profiles and shapes in various colors, materials, and configurations, including co-extrusions and tri-extrusions.

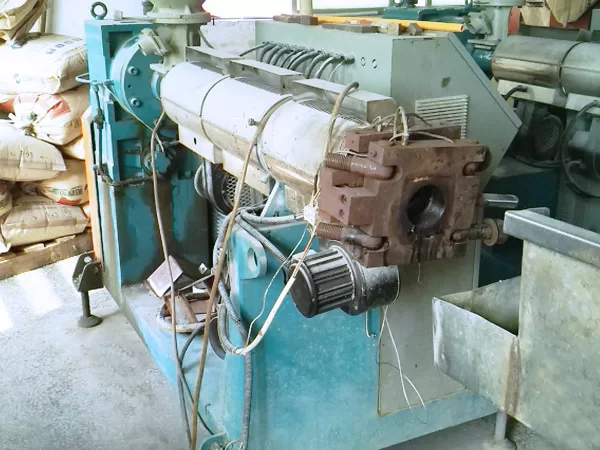

The custom plastic extrusion manufacturing process is a way to make plastic products. It starts with raw plastic materials, usually in small pellets. These pellets are melted and then squeezed or pushed through a machine under pressure to create a continuous shape or design. The process can make many different types of products, like custom plastic shapes, rods, tubes, edging, coatings, and even products made with multiple materials (called co-extrusion and tri-extrusion).

After extrusion, the plastic products can be used as is or further modified with techniques like punching, drilling, or printing. Extruded plastic products are cost-effective for making and assembling various products.

Pareto Plastic is a top company that specializes in making custom plastic profiles. We can make almost any shape or design you can imagine, using a wide range of plastic materials. We also excel in making products with multiple materials or colors (co-extrusion and tri-extrusion).

Pareto Plastic offers many additional services to meet all your production needs, like punching, milling, drilling, printing, and product assembly. We have been in the industry for 20 years and are known for our high-quality products and excellent customer service. With 10 main production lines and 3 co-extrusion lines, we can handle orders of all sizes, from small prototypes to large-scale production.

Contact Us for Plastic Extrusion Manufacturing

Outsource your plastic extrusion projects to China for affordable, efficient manufacturing.