Custom Plastic Co-Extrusion and Tri-Extrusion Manufacturer

We are a leading custom plastic co-extrusion and tri-extrusion manufacturer in China, specializing in the production of high-quality, customized plastic extrusions for a wide range of industries.

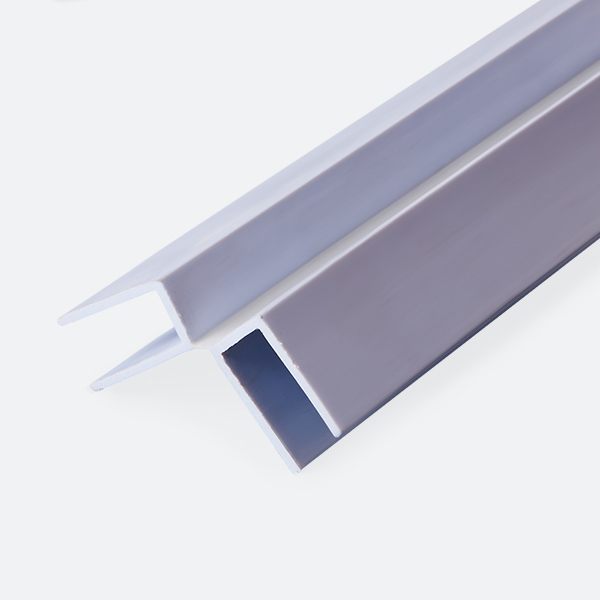

Custom Plastic Co-Extrusion and Tri-Extrusion Projects

Utilizing state-of-the-art co-extrusion and tri-extrusion technology, we are able to produce multi-layer plastic products with enhanced properties such as improved strength, barrier properties, and aesthetics.

Custom Plastic Co-Extrusion and Tri-Extrusion Molding

Our experienced engineers work closely with you to develop a customized co-extrusion or tri-extrusion profile that incorporates the optimal combination of materials and layers to achieve your desired properties, such as strength, durability, barrier resistance, and aesthetics.

Your Reliable Partner for Custom Plastic Co-Extrusion and Tri-Extrusion Manufacturing

Co-extrusion and tri-extrusion are pioneering manufacturing techniques that involve the simultaneous extrusion of two or more thermoplastic materials through a single die featuring multiple openings. This innovative approach enables the seamless integration of multiple plastic layers into a single, cohesive part, offering unparalleled versatility and customization.

Advantages of Co-Extrusion and Tri-Extrusion

At Pareto Plastic, we harness the power of co-extrusion and tri-extrusion to combine up to three unique raw materials into a single extruded profile. This process boasts several key benefits, including:

- Diverse Finishes and Colors: The ability to incorporate multiple colors and finishes within a single part, creating visually striking and functional designs.

- Rigid and Soft Material Combinations: Combining rigid and soft materials to create parts with enhanced durability and user-friendliness.

- Cost-Effective Solutions: Tailored to meet specific client needs while maintaining cost-efficiency.

- Unique Properties: Each layer can impart distinct properties such as rigidity, flexibility, heat resistance, or chemical impermeability, impossible to achieve with a single material.

Applications of Co-Extruded and Tri-Extruded Parts

The versatility of co-extrusion and tri-extrusion makes it ideal for a wide range of applications, including:

- Packaging Materials: Creating packaging with superior barrier properties for food, pharmaceuticals, and other sensitive products.

- Automotive Components: Designing intricate automotive parts with optimized strength, durability, and weight.

- Multi-Layer Tubings: Producing multi-functional tubing for various industries, such as medical, fluid transfer, and construction.

- Rigid Parts with Flexible Hinges: Crafting rigid parts with integrated flexible hinges for enhanced usability and durability.

- Custom POP Displays: Manufacturing custom point-of-purchase displays with colorful designs and flexible gripping elements.

Expertise and Capabilities at Pareto Plastic

At Pareto Plastic, we possess the expertise and capabilities to configure and extrude a diverse range of multi-layer plastic profiles. Our team of skilled engineers and technicians can work closely with you to ensure that your custom plastic extrusion requirements are met with precision and efficiency. For more information or to request a quotation, please contact our sales engineers today.

Contact Us for Custom Plastic Co-Extrusion and Tri-Extrusion

Get in touch with us today for all your custom plastic co-extrusion and tri-extrusion needs. Our team of experts is dedicated to providing you with the highest quality multi-layer plastic profiles tailored to your specific requirements.