The durability of extruded plastic profiles is influenced by various factors, including material selection, production processes, environmental conditions, and maintenance. Modern plastic profiles, however, have undergone significant advancements in design and manufacturing, resulting in increased durability and suitability for a wide range of applications.

Material Selection of Extruded Plastic Profiles

The choice of plastic extrusion material is crucial in determining a profile’s durability. Different materials offer varying properties like hardness, weather resistance, corrosion resistance, and temperature tolerance. For instance, PVC is commonly used in construction due to its excellent weather resistance and chemical stability, ensuring long-lasting performance.

Extruded Plastic Profiles Production Process

Advanced extrusion molding technology, precise control systems, and rigorous quality management play a vital role in enhancing durability. These factors contribute to dimensional accuracy, surface smoothness, and a strong internal structure. Additionally, incorporating stabilizers and anti-ultraviolet agents can further improve weather resistance and prevent aging.

Environmental Factors

Exposure to extreme temperatures, high humidity, direct sunlight, or corrosive environments can accelerate the degradation of plastic profiles. Careful consideration of the intended use environment is essential. Protective measures like awnings and regular cleaning can help mitigate these effects.

Maintenance of Extruded Plastic Profiles

Proper maintenance is crucial for preserving the durability of plastic profiles. Regularly cleaning, checking for loose connections, and promptly addressing damage can prevent issues from escalating and prolong the product’s lifespan.

Conclusion

By combining thoughtful material selection, advanced manufacturing techniques, appropriate environmental considerations, and regular maintenance, extruded plastic profiles can achieve a high level of durability. However, it’s important to remember that all materials have a lifespan. Careful evaluation of specific needs and expectations will help determine the most suitable choice for your application.

Pareto Plastic: Your Trusted Partner for Custom Plastic Extrusion

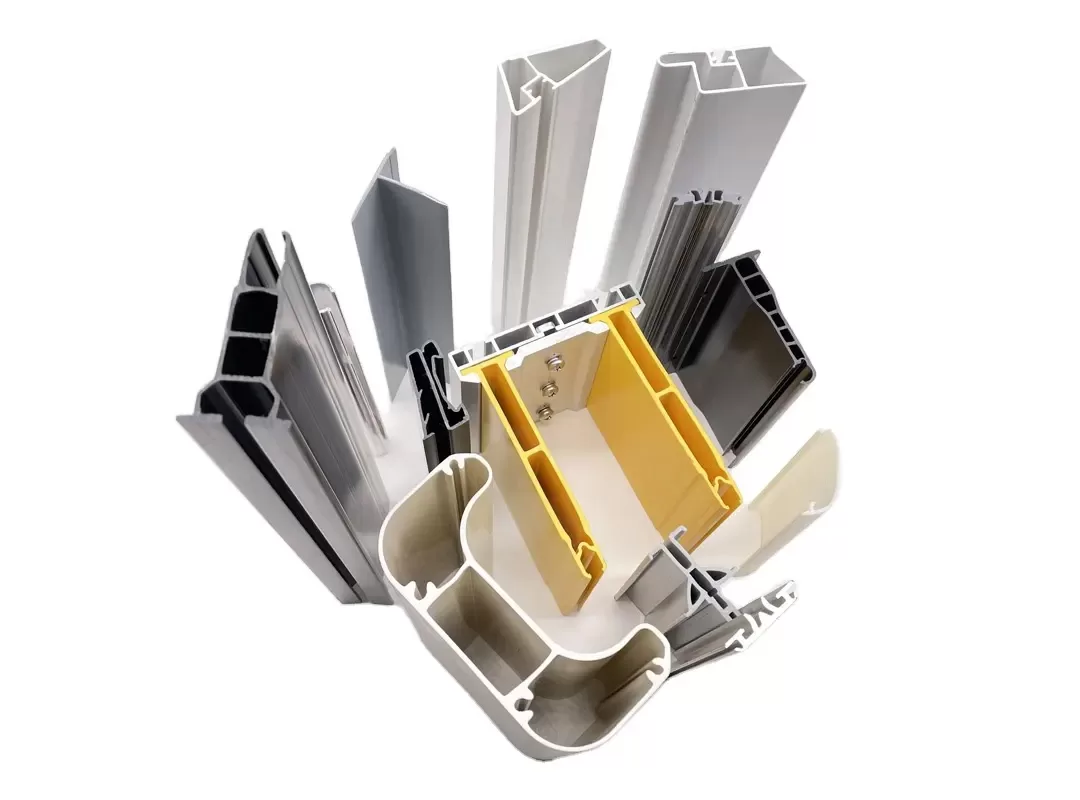

Pareto Plastic specializes in producing custom extruded plastic profiles. We offer a wide range of plastic extrusion products, including PVC profiles, ABS profiles, PP profiles, PC lampshades, plastic pipes, and more. Our expertise in design, customization, mold development, processing, and production ensures that we can deliver tailored solutions to meet your unique requirements.