Residential window and door weatherstripping is an essential component for sealing gaps around windows and doors, preventing air and water leaks while enhancing energy efficiency. Properly installed weatherstripping keeps homes comfortable, reduces energy costs, and protects against moisture and outdoor elements. In recent years, plastic profile extrusion has become the preferred method for manufacturing high-quality weatherstripping due to its precision, cost-effectiveness, and ability to produce custom profiles.

What is Residential Window & Door Weatherstripping?

Weatherstripping is a narrow strip or seal installed along the edges of windows and doors to prevent drafts, moisture, and dust from entering the home. For residential applications, weatherstripping is vital for maintaining indoor comfort, energy efficiency, and structural integrity. It serves as a protective barrier, improving insulation and minimizing the effects of external temperature changes.

Common materials used for residential window and door weatherstripping include plastic, rubber, foam, and metal. Among these, plastic weatherstripping, particularly those made from PVC (Polyvinyl Chloride), is widely used for its durability, flexibility, and affordability.

Benefits of Plastic Profile Extrusion for Weatherstripping

The plastic profile extrusion process offers significant benefits when it comes to manufacturing residential window and door weatherstripping. Here’s why extrusion is the ideal method:

- Precision Manufacturing: Extrusion creates weatherstripping with exact dimensions, ensuring a perfect fit for various window and door frames.

- Durability: Extruded plastic weatherstripping is highly resistant to wear, moisture, UV rays, and temperature fluctuations, offering long-lasting performance.

- Customization: The extrusion process allows for the creation of custom profiles that can meet specific design needs for residential projects.

- Cost-Effective: Plastic extrusion is a cost-efficient process, offering a more affordable solution compared to materials like metal, while still providing excellent insulation.

- Low Maintenance: Plastic weatherstripping requires minimal upkeep, as it does not warp, rot, or corrode like other materials, making it a practical choice for homeowners.

Types of Plastic Weatherstripping for Residential Use

There are several types of plastic weatherstripping available, each serving different purposes based on the type of window or door and the climate conditions. Common types include:

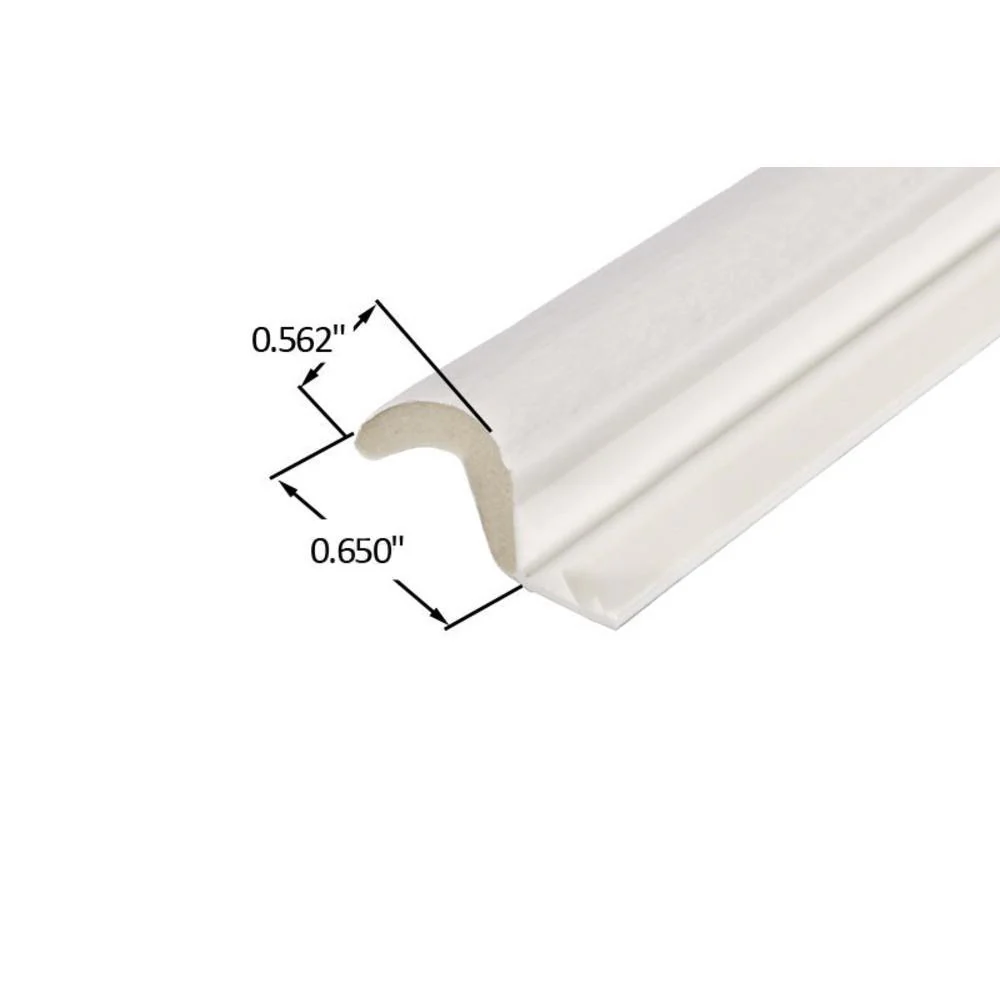

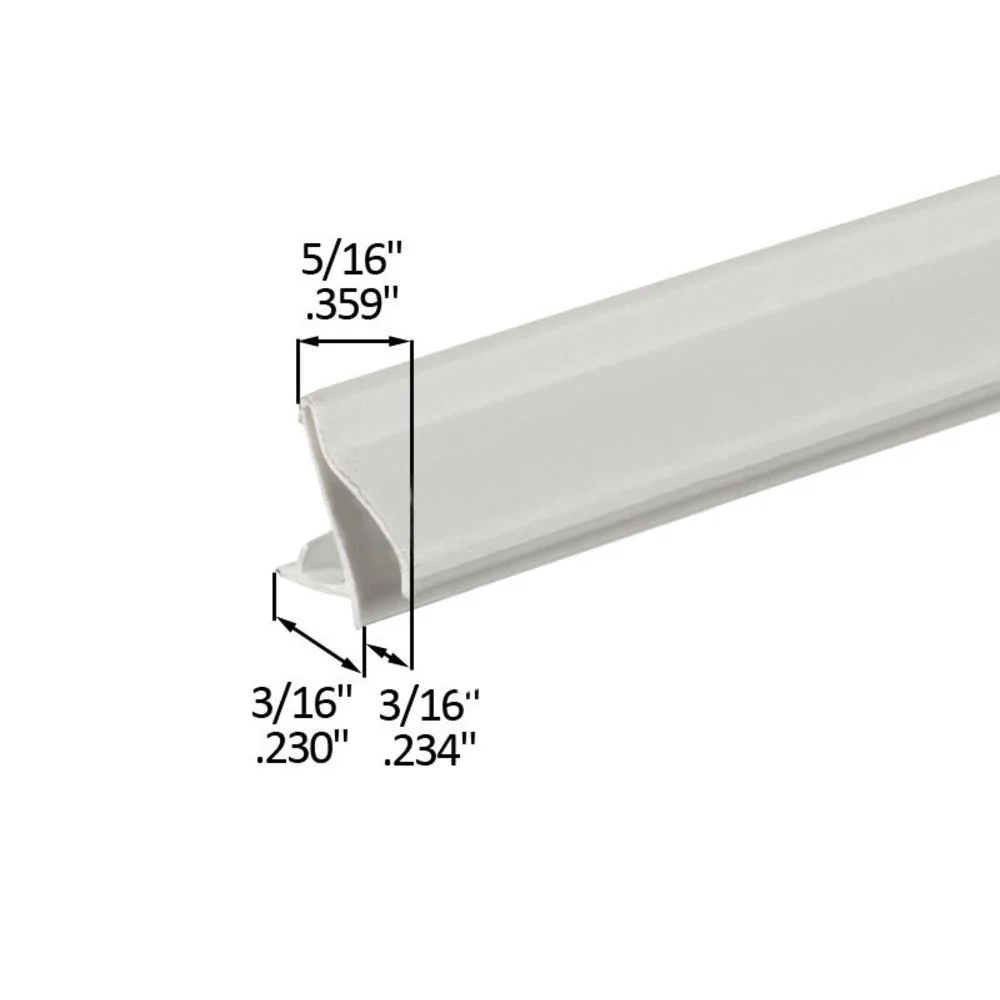

- V-Seal Weatherstripping: Shaped like a “V”, this flexible plastic seal is used to create a tight barrier along the sides of window sashes and door frames, preventing drafts and air leaks.

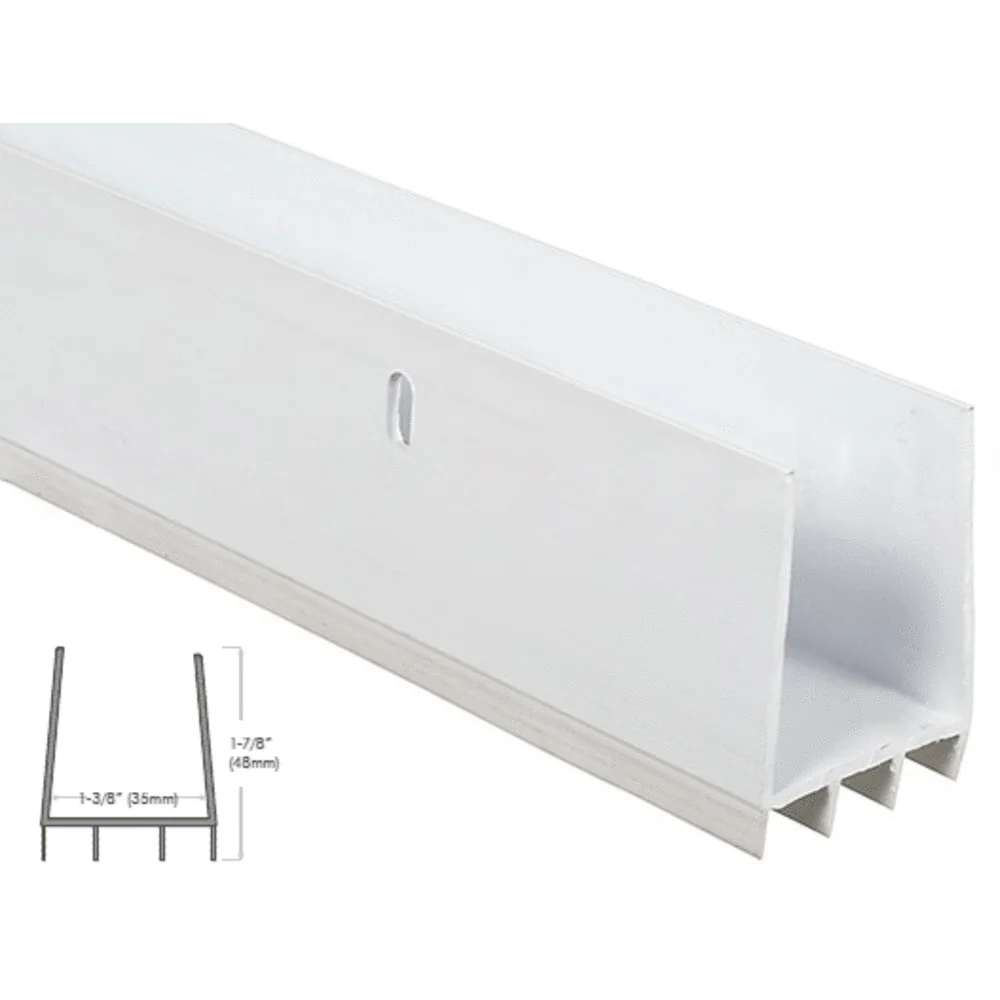

- Compression Weatherstripping: Made from durable PVC or foam, this type of weatherstripping is placed along the bottom and sides of doors and windows. It compresses when the window or door is closed, forming a tight seal.

- Bulb or Gasket Weatherstripping: A rounded, flexible plastic or rubber profile that is installed along the edges of windows and doors to provide a cushioned, airtight seal.

- Magnetic Weatherstripping: Often used in doors, this type of weatherstripping features a magnetic strip encased in plastic, creating an airtight seal around metal door frames.

Why Plastic Weatherstripping is Ideal for Residential Windows and Doors

Plastic weatherstripping offers a range of advantages that make it the ideal choice for residential applications. Here’s why:

- Energy Efficiency: By preventing air leaks, plastic weatherstripping improves insulation, leading to lower heating and cooling costs.

- Weather Resistance: Plastic materials like PVC and TPE are resistant to moisture, UV rays, and temperature fluctuations, ensuring that weatherstripping maintains its effectiveness over time.

- Flexible and Easy to Install: Plastic weatherstripping is lightweight, flexible, and can easily be cut to size, making it simple to install for homeowners and contractors alike.

- Long Lifespan: Due to its resistance to environmental wear and tear, plastic weatherstripping has a longer lifespan compared to materials like foam or felt, reducing the need for frequent replacements.

The Role of Weatherstripping in Energy Efficiency

One of the primary functions of residential window and door weatherstripping is to improve energy efficiency. By sealing gaps around doors and windows, weatherstripping prevents drafts, reduces heat loss, and maintains indoor temperatures. This is especially important in regions with extreme weather conditions, where inefficient insulation can lead to significant energy losses.

In addition to reducing energy consumption, properly installed weatherstripping helps homeowners save on utility bills by reducing the need for heating and cooling systems to work harder. The result is a more energy-efficient home with a smaller carbon footprint.

Environmental Benefits of Plastic Weatherstripping

Plastic weatherstripping not only provides practical benefits for homeowners but also contributes to environmental sustainability:

- Recyclability: Many plastic materials used in weatherstripping, such as PVC, are recyclable, reducing the environmental impact of manufacturing and disposal.

- Energy-Efficient Production: The extrusion process is energy-efficient, producing weatherstripping with minimal waste.

- Longevity: The durability of plastic weatherstripping means less frequent replacements, which conserves resources and reduces waste.

Conclusion: The Value of Plastic Profile Extrusion for Residential Weatherstripping

The plastic profile extrusion process is the most efficient and precise method for producing durable, flexible, and cost-effective residential window and door weatherstripping. Plastic weatherstripping offers numerous benefits, including enhanced energy efficiency, weather resistance, and long-term durability, making it a smart investment for homeowners looking to improve the performance and sustainability of their homes.