In today’s global manufacturing landscape, China plastic extrusion has become a popular choice for businesses seeking cost-effective and high-quality custom plastic profiles. China is home to a vast network of experienced manufacturers that offer cutting-edge technology, competitive pricing, and fast turnaround times. When it comes to custom plastic extrusion, partnering with a Chinese supplier can provide significant advantages that help companies stay competitive in the global market.

Why Choose China for Plastic Extrusion?

China has established itself as a leading hub for manufacturing, including custom plastic extrusion services. Here are some reasons why businesses worldwide choose China for their plastic extrusion projects:

1. Cost-Effective Manufacturing

One of the most compelling reasons to opt for China plastic extrusion is the significant cost savings. China offers a competitive advantage in terms of lower labor and operational costs, allowing manufacturers to produce high-quality extruded plastic profiles at a fraction of the cost compared to Western countries. This cost efficiency translates into lower product prices, helping businesses improve their profit margins without compromising on quality.

2. Advanced Technology and Expertise

Chinese plastic extrusion manufacturers have invested heavily in modern technology and equipment, ensuring they can produce complex and precise plastic profiles. With advanced extrusion machinery, manufacturers can offer a wide range of services, including co-extrusion, tri-extrusion, and multi-material extrusion. Additionally, many Chinese factories have extensive experience in handling various thermoplastic materials, such as PVC, ABS, polycarbonate, acrylic, and polypropylene, providing flexibility for custom projects.

3. High-Quality Standards

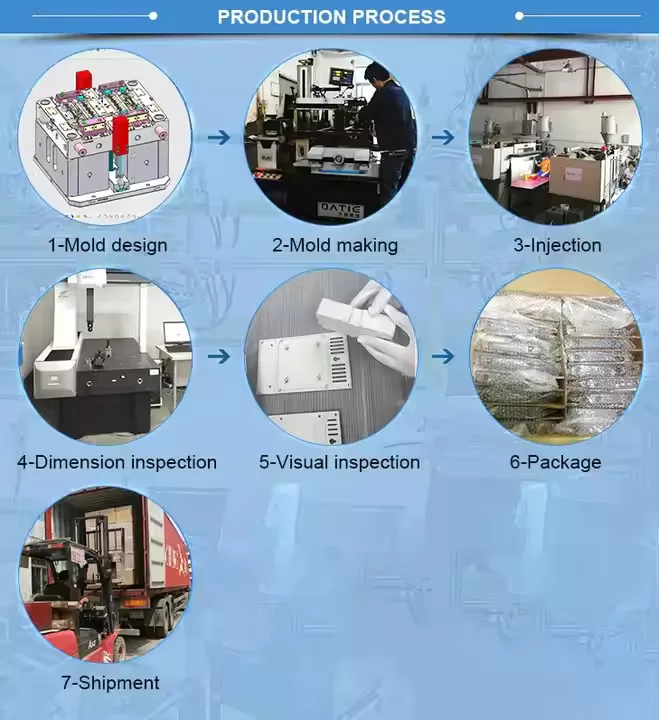

Contrary to common misconceptions, Chinese manufacturers are known for maintaining strict quality control standards. Many China plastic extrusion companies are ISO-certified and adhere to international standards, ensuring that their products meet the highest quality requirements. By partnering with a reputable Chinese supplier, businesses can expect high-quality extruded plastic profiles that meet their exact specifications.

Key Benefits of China Plastic Extrusion

Opting for China plastic extrusion offers several advantages that can enhance your overall manufacturing process and business operations.

1. Customization and Flexibility

Chinese manufacturers excel at producing customized plastic extrusions tailored to specific project needs. Whether you need unique shapes, sizes, or material combinations, Chinese extrusion companies can provide custom solutions to meet your exact requirements. Their ability to offer flexible production options makes it easier to adapt designs to different applications, whether for the automotive, construction, electronics, or packaging industries.

2. Fast Production and Delivery

One of the biggest advantages of choosing China plastic extrusion is the speed at which projects can be completed. With large-scale production capacities and streamlined supply chains, Chinese manufacturers can handle both small and large-volume orders with quick turnaround times. This ability to deliver projects faster than many Western manufacturers can be a significant advantage for companies looking to meet tight deadlines or market demands.

3. Wide Range of Materials

China’s plastic extrusion industry is highly versatile, offering extrusion services with a wide range of thermoplastic materials. These include:

- PVC

- ABS

- Polypropylene

- Polycarbonate

- PETG

- Acrylic (PMMA)

This diversity in material selection allows for a broad range of applications across various industries, ensuring that manufacturers can find the right material for each specific use case, whether it’s for durable outdoor profiles, transparent diffusers, or flexible piping.

4. Competitive Global Shipping

China’s robust logistics infrastructure makes global shipping both efficient and cost-effective. Manufacturers in China can ship extruded plastic products to any part of the world, thanks to well-established export networks. Even with long-distance shipping, many companies find that the overall cost remains competitive, given the reduced manufacturing expenses.

5. Scalability for Large Projects

China’s plastic extrusion industry is equipped to handle high-volume production runs without sacrificing quality or speed. This scalability is ideal for businesses looking to ramp up production for large projects or seasonal demands. Whether you need thousands of plastic profiles or a smaller batch of custom parts, Chinese manufacturers have the capacity to deliver at scale.

Industries That Benefit from China Plastic Extrusion

Many industries can take advantage of China plastic extrusion to optimize production costs while ensuring high-quality components. Some of the key industries benefiting from this manufacturing process include:

- Automotive: Custom plastic profiles for interior and exterior components, such as trims and seals.

- Construction: Durable extruded plastic products for window frames, piping, and building materials.

- Lighting: High-quality diffusers, lenses, and housings for LED lighting.

- Electronics: Protective casings and profiles for electronic devices and components.

- Packaging: Custom extruded plastic profiles for packaging solutions.

How to Choose the Right China Plastic Extrusion Supplier

When selecting a China plastic extrusion supplier, it’s important to consider several factors to ensure you’re partnering with a reputable manufacturer:

1. Experience and Expertise

Look for a supplier with extensive experience in plastic extrusion and a proven track record in your specific industry. Ask for case studies or references to understand their capabilities and reliability.

2. Quality Control

Ensure that the manufacturer follows strict quality control procedures and adheres to international standards like ISO certification. Request samples to evaluate their product quality before committing to large orders.

3. Communication and Support

Effective communication is key when working with an overseas supplier. Choose a manufacturer that offers clear, responsive communication and customer support throughout the production process to avoid any misunderstandings or delays.

4. Logistics and Shipping

Consider the supplier’s ability to handle international shipping efficiently. Ensure they have experience with global exports and can deliver products within the agreed-upon timeline.

Conclusion: The Future of China Plastic Extrusion

As global manufacturing continues to evolve, China plastic extrusion remains a valuable solution for businesses looking to balance cost efficiency, customization, and high-quality production. With their advanced technology, competitive pricing, and ability to scale, Chinese manufacturers offer significant benefits to companies across various industries.

By partnering with a reliable China plastic extrusion supplier, you can streamline your production process, reduce costs, and access the expertise needed to produce high-quality custom plastic components tailored to your specific needs.