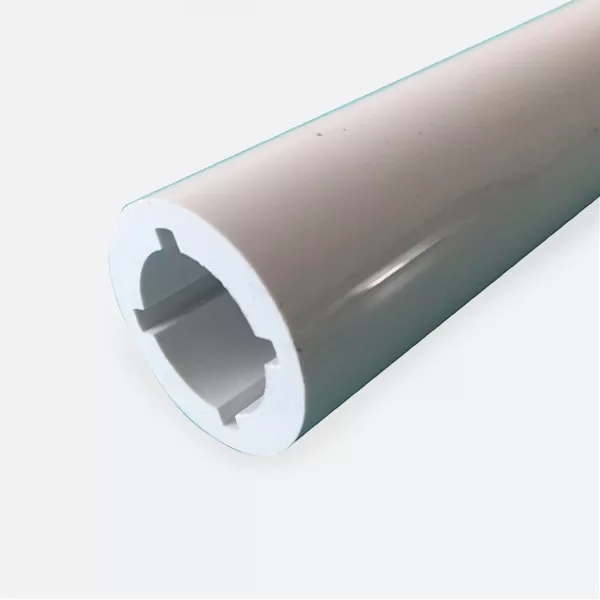

PE (Polyethylene) plastic pipes have become increasingly popular in various industries due to their numerous advantages. Known for their durability and versatility, PE plastic pipes offer an array of benefits that make them an ideal choice for water supply, gas distribution, and other applications.

1. Exceptional Temperature Resistance

One of the standout features of PE plastic pipes is their excellent temperature resistance. These pipes can function effectively in a temperature range of -75℃ to 40℃, making them suitable for both cold and warm environments. Their low embrittlement temperature ensures that they remain flexible and durable, even in harsh winter conditions. This temperature resilience prevents brittle cracking during installation and use, providing reliable performance year-round.

2. Outstanding Chemical Resistance

PE plastic pipes exhibit remarkable chemical stability, capable of withstanding a wide range of acidic and alkaline substances. While they are not resistant to oxidizing acids, their inert nature allows them to resist corrosion from various chemical media without the need for additional anti-corrosion protection. This feature makes PE plastic pipes an excellent choice for applications where chemical exposure is a concern.

3. Flexibility and Seismic Resistance

Another significant advantage of PE plastic pipes is their impressive flexibility. With an elongation at break exceeding 800%, these pipes can withstand local vibrations without transferring stress throughout the entire system. This flexibility provides strong seismic resistance, ensuring that the pipelines remain intact and functional even in earthquake-prone areas.

4. High Pressure Resistance

PE plastic pipes are designed with high-density polyethylene (HDPE), which enhances their strength and hardness. This high crystallinity allows them to withstand significant internal pressure, making them suitable for water supply and gas pressure pipelines. The welding process used in the manufacturing of these pipes ensures tight seals, further enhancing their pressure resistance.

5. Sanitary and Non-Toxic Properties

Safety and health are paramount in any pipeline application. PE plastic pipes are non-toxic and do not promote the growth of bacteria. As a result, they prevent secondary pollution of the water supply, ensuring that the water remains clean and safe for consumption. This sanitary feature makes PE plastic pipes an excellent choice for drinking water applications.

6. Efficient Flow Capacity

The inner surface of PE plastic pipes is smooth, which significantly reduces the friction coefficient. This characteristic leads to lower fluid resistance and minimal head loss during transportation. As a result, PE plastic pipes can deliver water efficiently, reducing pressure loss and energy consumption. This efficiency translates to significant economic benefits for businesses and municipalities alike.

7. Longevity and UV Resistance

PE black pipes contain approximately 2.5% carbon black, which provides strong resistance to ultraviolet (UV) radiation. This UV stability enables the pipes to be stored and used outdoors without degrading over time. With a service life of up to 50 years, PE plastic pipes are a long-term investment that ensures reliability and durability.

Conclusion

In summary, PE plastic pipes offer a multitude of benefits, including exceptional temperature and chemical resistance, flexibility, pressure resistance, and sanitary properties. Their efficient flow capacity and long service life further enhance their appeal for various applications. If you’re considering pipeline solutions for water supply, gas distribution, or other needs, PE plastic pipes should be at the top of your list. Their versatility and durability make them an ideal choice for modern infrastructure projects.