Plastic profile extrusion plays a pivotal role in the construction industry, providing versatile solutions that enhance both functionality and aesthetics in various applications. This comprehensive guide explores the significance of plastic profile extrusion, its applications in construction, and the benefits it brings to modern building projects.

What is Plastic Profile Extrusion?

Plastic profile extrusion is a manufacturing process that involves melting plastic materials and shaping them into continuous profiles using a die. This method is widely utilized in construction due to its ability to produce customized shapes and sizes, catering to specific project requirements. Common materials used in plastic extrusion include PVC, ABS, and polyethylene, each offering unique properties suited for various applications.

Key Applications of Plastic Profile Extrusion in Construction

1. Window and Door Frames

One of the most significant applications of plastic profile extrusion is in the production of window and door frames. PVC profiles are particularly popular due to their:

- Durability: Resistant to weathering and corrosion.

- Energy Efficiency: Provides excellent insulation, helping to reduce energy costs.

- Low Maintenance: Requires minimal upkeep compared to traditional materials like wood.

2. Roofing and Siding

Plastic extrusions are commonly used in roofing and siding materials, offering several advantages:

- Lightweight: Easier to handle and install compared to heavier materials.

- Weather Resistance: Designed to withstand harsh environmental conditions.

- Aesthetic Flexibility: Available in various colors and finishes, allowing for creative architectural designs.

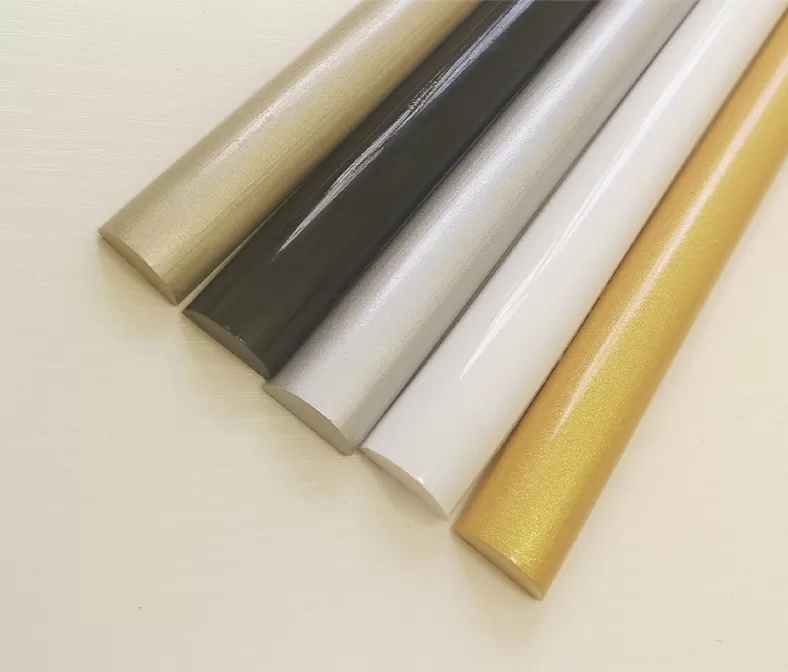

3. Interior Trim and Molding

Plastic profile extrusion is ideal for creating interior trim and molding elements, enhancing the aesthetic appeal of residential and commercial spaces. Benefits include:

- Customizability: Tailored designs to fit specific architectural styles.

- Moisture Resistance: Ideal for areas prone to humidity, such as bathrooms and kitchens.

- Ease of Installation: Lightweight and easy to work with, speeding up the construction process.

4. Fencing and Decking

In outdoor applications, plastic extrusions are used to produce durable fencing and decking materials. Key benefits include:

- Low Maintenance: Unlike wood, plastic does not require staining or sealing.

- Longevity: Resistant to rot, splintering, and insect damage.

- Environmental Resistance: Suitable for various climates, maintaining integrity over time.

Advantages of Plastic Profile Extrusion in Construction

1. Cost-Effectiveness

Plastic profile extrusion offers a cost-effective solution for construction projects. The efficient manufacturing process reduces material waste and allows for mass production, ultimately lowering overall project costs.

2. Sustainability

Many plastic materials used in extrusion can be recycled, making them a more sustainable choice compared to traditional building materials. By opting for plastic profile extrusion, construction companies can reduce their environmental footprint.

3. Design Flexibility

Plastic profile extrusion allows for an array of custom shapes and sizes, enabling architects and designers to bring their creative visions to life. This flexibility can lead to innovative building solutions that stand out in the marketplace.

4. Quick Installation

The lightweight nature of plastic profiles speeds up installation times, allowing construction projects to progress more rapidly. This efficiency can be a significant advantage in meeting tight deadlines.

Considerations When Choosing Plastic Profile Extrusion

When selecting plastic profile extrusion for construction projects, consider the following factors:

- Material Properties: Evaluate the specific requirements of your project, such as durability, thermal insulation, and resistance to chemicals.

- Environmental Conditions: Ensure that the chosen materials can withstand the local climate and environmental factors.

- Compliance: Verify that the products meet relevant building codes and standards.

Conclusion

Plastic profile extrusion is a game-changer in the construction industry, providing innovative, cost-effective, and sustainable solutions for various applications. From window frames to fencing, the versatility and durability of plastic extrusions make them an essential component of modern construction.

By understanding the advantages and applications of plastic profile extrusion, construction professionals can make informed decisions that enhance their projects. As the industry continues to evolve, embracing plastic extrusion technology will be key to staying competitive and meeting the demands of today’s construction market.