In residential construction, PVC window stops are crucial components that help secure and seal windows, ensuring energy efficiency and weather resistance. The process used to manufacture these essential parts is plastic profile extrusion, a highly efficient and precise method of creating consistent PVC profiles.

What is a PVC Window Stop?

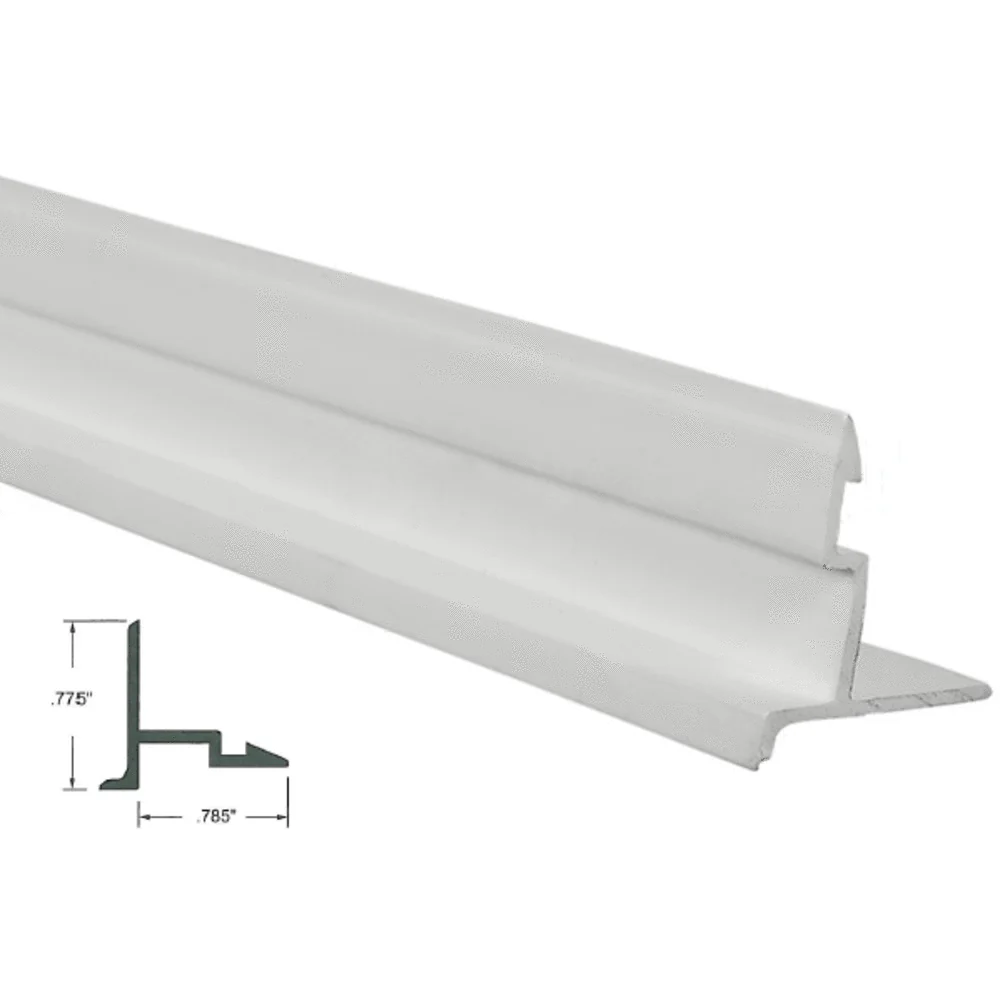

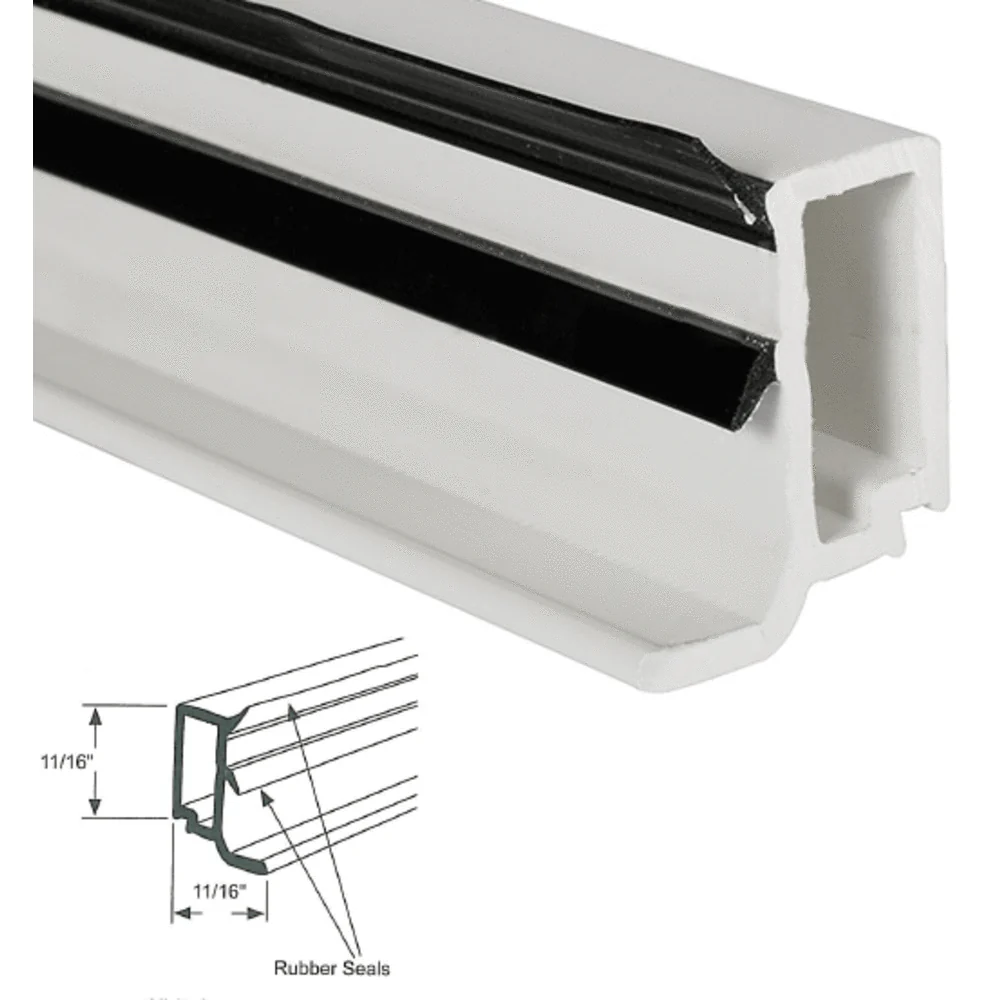

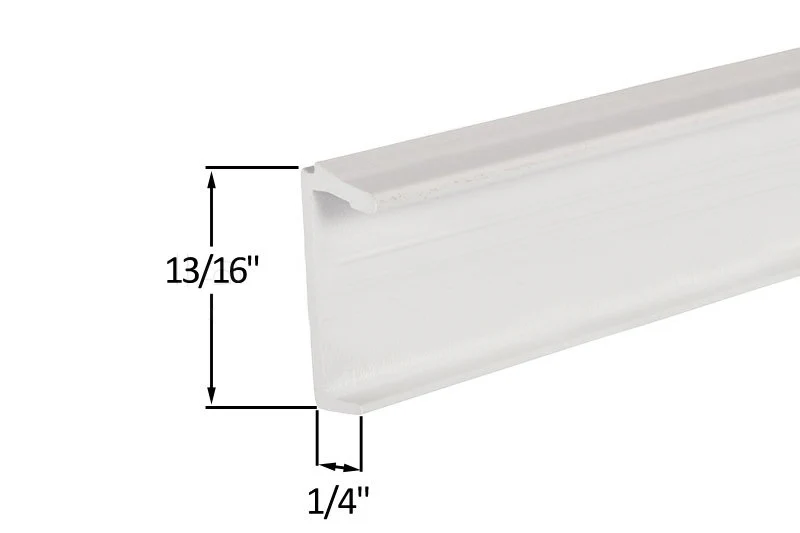

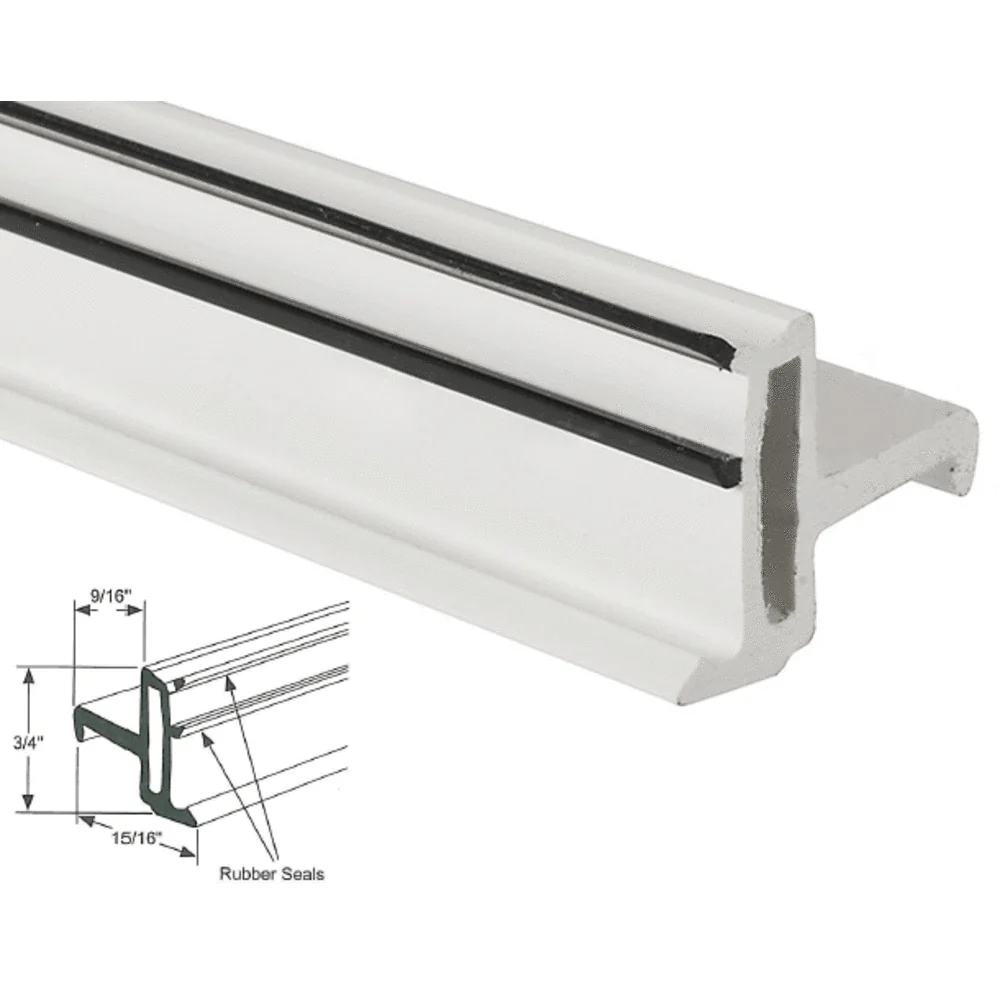

A PVC window stop is a narrow strip installed in window frames to hold the glass securely in place and prevent air or water infiltration. This simple yet effective component enhances a window’s insulation, durability, and overall performance. PVC window stops are commonly used in residential projects due to their cost-effectiveness, ease of maintenance, and resistance to environmental factors.

Key Benefits of PVC Window Stops

PVC window stops offer numerous benefits that make them the preferred choice in residential window installations:

- Durability: PVC is a long-lasting material that is highly resistant to moisture, UV rays, and temperature fluctuations.

- Energy Efficiency: Properly installed window stops help seal gaps around windows, reducing drafts and improving home insulation, leading to lower energy costs.

- Low Maintenance: Unlike wood or metal, PVC does not warp, rot, or rust. It requires no painting or sealing, making it a low-maintenance solution for homeowners.

- Cost-Effective: PVC is an affordable material compared to wood or aluminum, making PVC window stops a cost-efficient choice for both builders and homeowners.

- Aesthetic Versatility: Available in various colors, shapes, and finishes, PVC window stops can be customized to match any window design.

The Plastic Profile Extrusion Process for PVC Window Stops

The plastic profile extrusion process is crucial for creating consistent, high-quality PVC window stops that meet the exact specifications of modern residential windows. Here’s an overview of the key steps involved in the extrusion process:

1. Material Preparation

The process starts by blending PVC resin with various additives, such as stabilizers, UV inhibitors, and impact modifiers. These additives enhance the weather resistance, strength, and longevity of the PVC window stop.

2. Extrusion

The blended material is heated and pushed through an extruder, where it is formed into the desired shape by passing through a die. The die is precisely designed to create the specific profile of the PVC window stop.

3. Cooling

Once the profile is extruded, it passes through a cooling chamber, where the PVC solidifies into its final shape. The cooling process ensures the dimensional accuracy of the window stop.

4. Cutting and Sizing

After cooling, the extruded PVC is cut into precise lengths, typically designed to fit standard window sizes or customized for specific projects.

5. Quality Control

The final step in the extrusion process is quality control, where each PVC window stop is inspected for defects and measured for consistency. This ensures that every piece meets industry standards for residential installations.

Why Choose Plastic Profile Extrusion for PVC Window Stops?

The plastic profile extrusion process offers several advantages for producing PVC window stops, including:

- Precision Manufacturing: The extrusion process allows for exact tolerances, ensuring that every PVC window stop is consistent in size and shape, which is critical for seamless installation.

- High Production Efficiency: Extrusion is ideal for mass production, allowing manufacturers to produce large volumes of PVC window stops quickly and cost-effectively.

- Customization: The extrusion process enables the creation of custom profiles, allowing window stops to be tailored to fit specific window systems, designs, and finishes.

- Sustainability: Modern extrusion processes are energy-efficient, and many manufacturers recycle leftover materials, reducing waste.

The Role of PVC Window Stops in Energy Efficiency

One of the primary functions of a PVC window stop is to improve the energy efficiency of residential windows. By sealing gaps and preventing air and water infiltration, PVC window stops help maintain indoor temperatures and reduce energy consumption. This is especially important in regions with extreme weather conditions, where drafts can significantly increase heating or cooling costs.

PVC window stops also contribute to a home’s sustainability by enhancing the overall insulation of the building. This reduces the need for excessive use of heating and cooling systems, lowering both energy bills and the household’s carbon footprint.

The Environmental Benefits of PVC Window Stops

Modern PVC window stops are not only practical and cost-effective, but they also offer several environmental benefits:

- Recyclability: PVC is a recyclable material, and many manufacturers are committed to recycling PVC waste from the extrusion process.

- Longevity: The durability of PVC window stops reduces the need for frequent replacements, minimizing material consumption and waste over time.

- Energy Efficiency: By enhancing window insulation, PVC window stops help reduce energy consumption, contributing to a greener and more energy-efficient home.

Conclusion: The Value of Plastic Profile Extrusion for Residential PVC Window Stops

The use of plastic profile extrusion in manufacturing PVC window stops ensures precision, durability, and cost-effectiveness. For homeowners, builders, and contractors, the benefits of PVC window stops are clear: they enhance window performance, improve energy efficiency, and require minimal maintenance. Whether you’re upgrading existing windows or installing new ones, choosing high-quality PVC window stops produced through the extrusion process guarantees long-term value and reliability.