Plastic profiles, extruded shapes with complex cross-sections, are widely used in various industries. PVC resin is the primary base material, often combined with different additives and compounding agents to achieve desired properties. This article delves into the eight primary types of plastic profiles, highlighting their unique characteristics and applications.

1. Special-Shaped Pipes

Beyond traditional round and square pipes, special-shaped pipes offer diverse functionalities. Corrugated pipes, foamed sandwich pipes, wire-reinforced pipes, fiber-reinforced pipes, and sectioned pipes cater to specific structural and drainage needs.

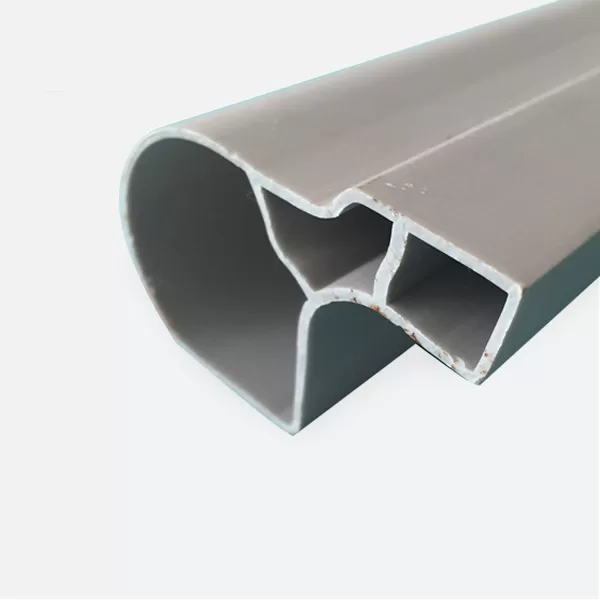

2. Closed Hollow Profiles

Closed hollow profiles feature a single or multiple holes within a completely closed cross-section. These profiles can incorporate horizontal rib partitions and varying wall thicknesses to meet specific design requirements.

3. Compartmental Profiles

Also known as compartmental medium-hole profiles, these profiles have branches extending from a single or multi-hole cross-section. They are commonly used in applications requiring internal compartments or channels.

4. Open Profiles

Open profiles lack a hollow chamber and are typically thin-walled. Examples include plastic eaves, stair anti-slip strips, skirting boards, and mirror lines.

5. Composite Profiles

Co-extrusion of two or more plastics with different properties creates composite profiles. A common example is a PVC skirting with a soft PVC bottom for enhanced ground sealing.

6. Inlaid Profiles

Inlaid profiles incorporate metal, wood, fabric, or other materials within the plastic extrusion process. This combination addresses potential plastic performance limitations, enhances decorative appeal, and leverages the strengths of both materials.

7. Core Profiles

Core profiles are extruded as solid blanks for further processing, such as machining or cutting. They serve as a foundation for various finished products.

8. Low Foaming Profiles

With a relative density of 0.6-0.95, low foaming profiles offer a lightweight alternative to traditional materials. They are commonly used in applications such as hanging mirror strips and stair handrails.

Conclusion

The versatility of plastic profiles is evident in their diverse types and characteristics. From specialized pipes to composite and inlaid options, these profiles cater to a wide range of industries and applications. The ease of shaping and processing plastics, combined with advanced extrusion techniques, ensures efficient production and a multitude of design possibilities.